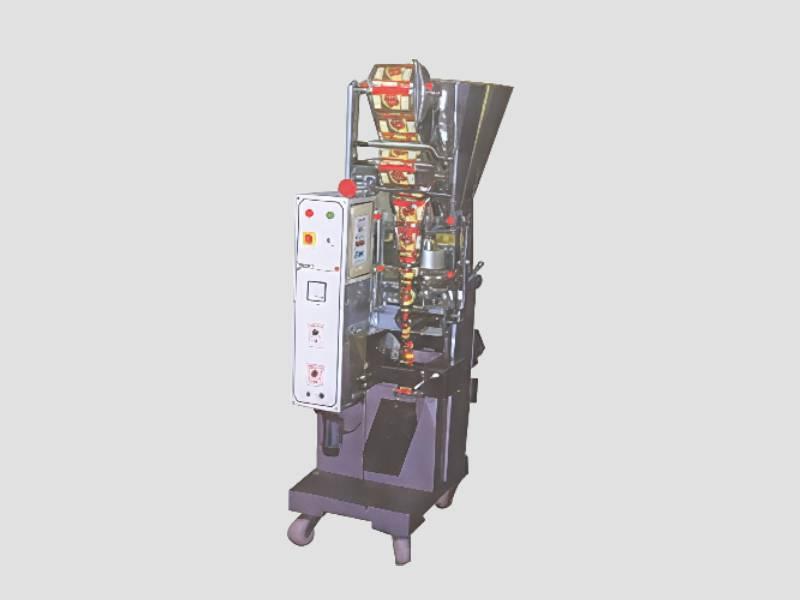

Form filling machines are used to create pouches from packaging film, fill them with product, and seal them securely. The machine supports different product types including powders, liquids and granules. Designed for consistent operation, it helps reduce manual handling and improves packaging efficiency. It is suitable for food processing and industrial packaging units requiring reliable pouch formation and filling.

Credit Card,PayPal,Cash,Cheque,Demand Draft

Key Attributes

Industry-specific Attributes

- Machine function Form fill and seal

- Operation mode Semi automatic

- Packaging format Flexible pouches

Other Attributes

- Material handling powder

- Usage sector Packaging industry

Pneumatic filling machines use compressed air to control filling operations for liquids and semi liquids. The system ensures consistent fill levels and smooth operation without electrical complexity. It is suitable for food, beverage and industrial applications where simple and reliable filling is required.

Credit Card,PayPal,Cash,Cheque,Demand Draft

Key Attributes

Industry-specific Attributes

- Filling type Liquid and semi liquid

- Operation method Pneumatic

- Accuracy level Controlled volume

Other Attributes

- Container type Bottles or pouches

- Usage sector Processing industries

Powder filling machines are used for accurate dosing and filling of powdered materials such as spices, flour and chemicals. The machine ensures uniform fill weight and reduces material wastage. Designed for ease of operation, it supports consistent output across production batches.

Credit Card,PayPal,Cash,Cheque,Demand Draft

Key Attributes

Industry-specific Attributes

- Filling type Powder materials

- Operation mode Semi automatic

- Dosing system Controlled powder dosing

Other Attributes

- Container type Pouches or containers

- Usage sector Food and industrial processing

Collar filling machines use a collar mechanism to shape packaging film into pouches before filling and sealing. The system supports smooth film movement and consistent pouch formation. It is suitable for packaging various products with uniform pouch size and sealing quality.

Credit Card,PayPal,Cash,Cheque,Demand Draft

Key Attributes

Industry-specific Attributes

- Forming method Collar based forming

- Operation mode Semi automatic

- Packaging format Flexible pouches

Other Attributes

- Product type Powder granule or liquid

- Usage sector Packaging industry

Collar type form filling machines combine pouch forming, product filling and sealing into a single system. The collar mechanism ensures accurate pouch shape and film alignment. Suitable for food and industrial packaging, the machine supports continuous operation with stable performance.

Credit Card,PayPal,Cash,Cheque,Demand Draft

Key Attributes

Industry-specific Attributes

- Machine type Form fill seal

- Forming system Collar type

- Operation mode Semi automatic or automatic

Other Attributes

- Packaging format Flexible pouches

- Usage sector Packaging industry